Sparks fly at Kearney: Students master trade skills, build go karts from scratch

FORT ST. JOHN – In a city grounded in forestry, oil and gas and agriculture, where the local economy relies on the types of fabrication that are taught in shop classes, metalwork and robotics teacher William McColm is giving middle school students the opportunity to learn hands-on skills that define our local region.

“The idea of course, is to introduce them to the trades early in middle school. Introduce them to the types of fabricating processes that are useful in industry, and to give them an opportunity to try them out,” said McColm. “And to start them thinking about what do their future careers look like, what are the needs of the local economy, and how can we, at the middle school, get them to start thinking about a career in the trades.”

“What better way to do it, than show them that their skills have a real-world application.”

When McColm took up the position at the metal shop at Dr. Kearney in September 2024, he wanted the metal shop experience to be grounded in the utility of the skills they were learning.

That’s how the Dr. Kearney Middle School After-School Go Kart Club was born.

It’s an after-school program that packs a big punch. The students are learning fabrication skills, shop safety skills, they’re thinking about trades and careers, they’re thinking about metalworking in an everyday useful context as something that’s exciting that they can feel successful at, and they’re also learning about power-train mechanics, electrical engineering concepts and they’re also learning about gas-powered trains.

And, they’re having a blast.

With 14 kids in the club this year, from Grades 7 to 9, there’s also a wide range of metalwork experience. Students who were in club last year are lending their experience to help newcomers.

“These kids don’t come to school anymore with that typical farm kid background, there are still a number of kids who have that farm kid background, but fewer and fewer of them bring that typical farm-kid skills with them. It means that I have to work with them from square one.”

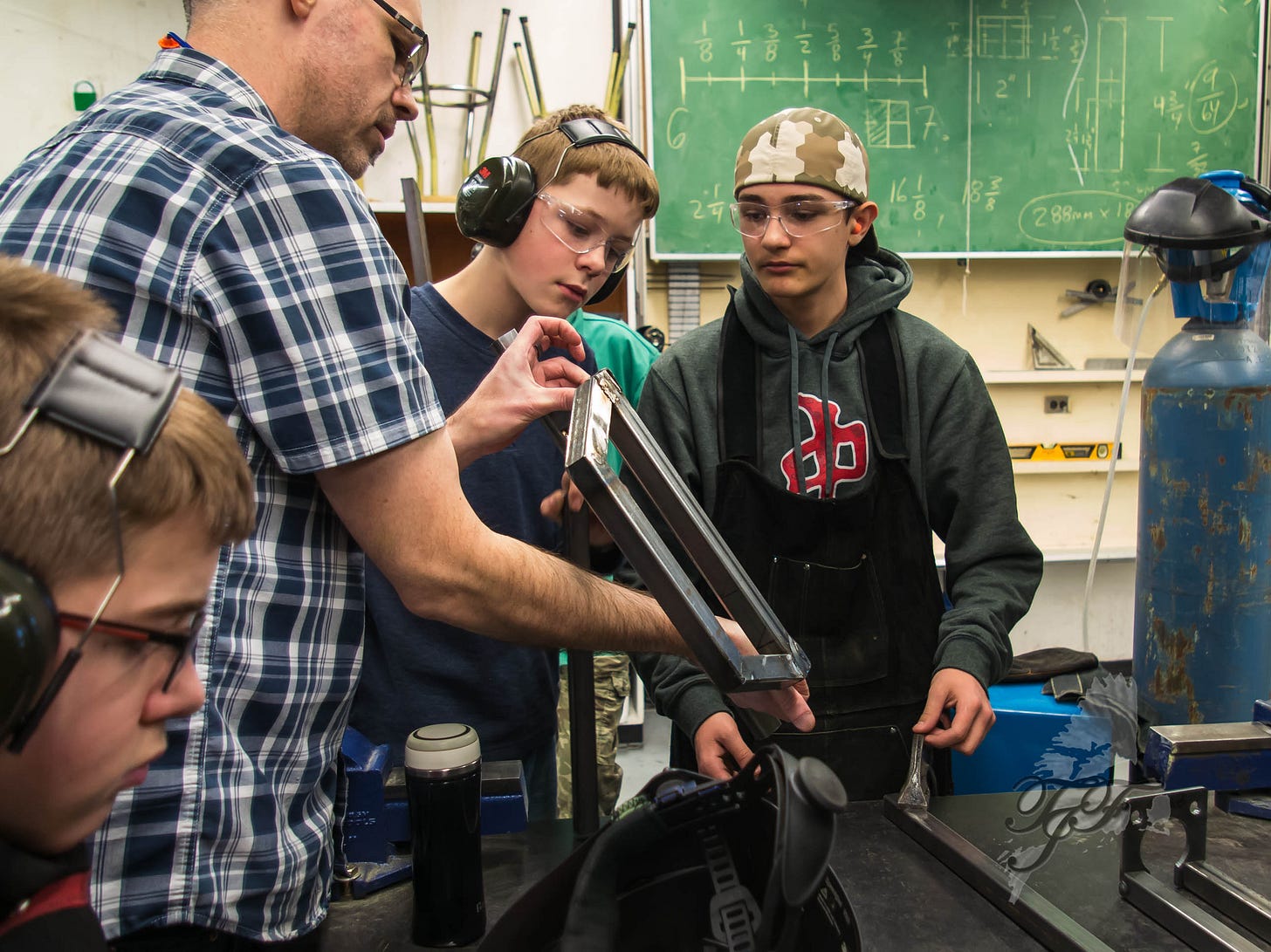

Before they get their hands on any tools, students are taught all the safety procedures, from wearing hearing protection, face shields, putting up screens to stop others from getting welding flash when the kids are welding, unplugging the saw ahead of time before doing anything, safety is paramount, McColm said.

“When you lose your fear of the machine, that’s when it hurts you.”

At the beginning of the year, many of the kids didn’t even know how to use a measuring tape or how to measure in inches.

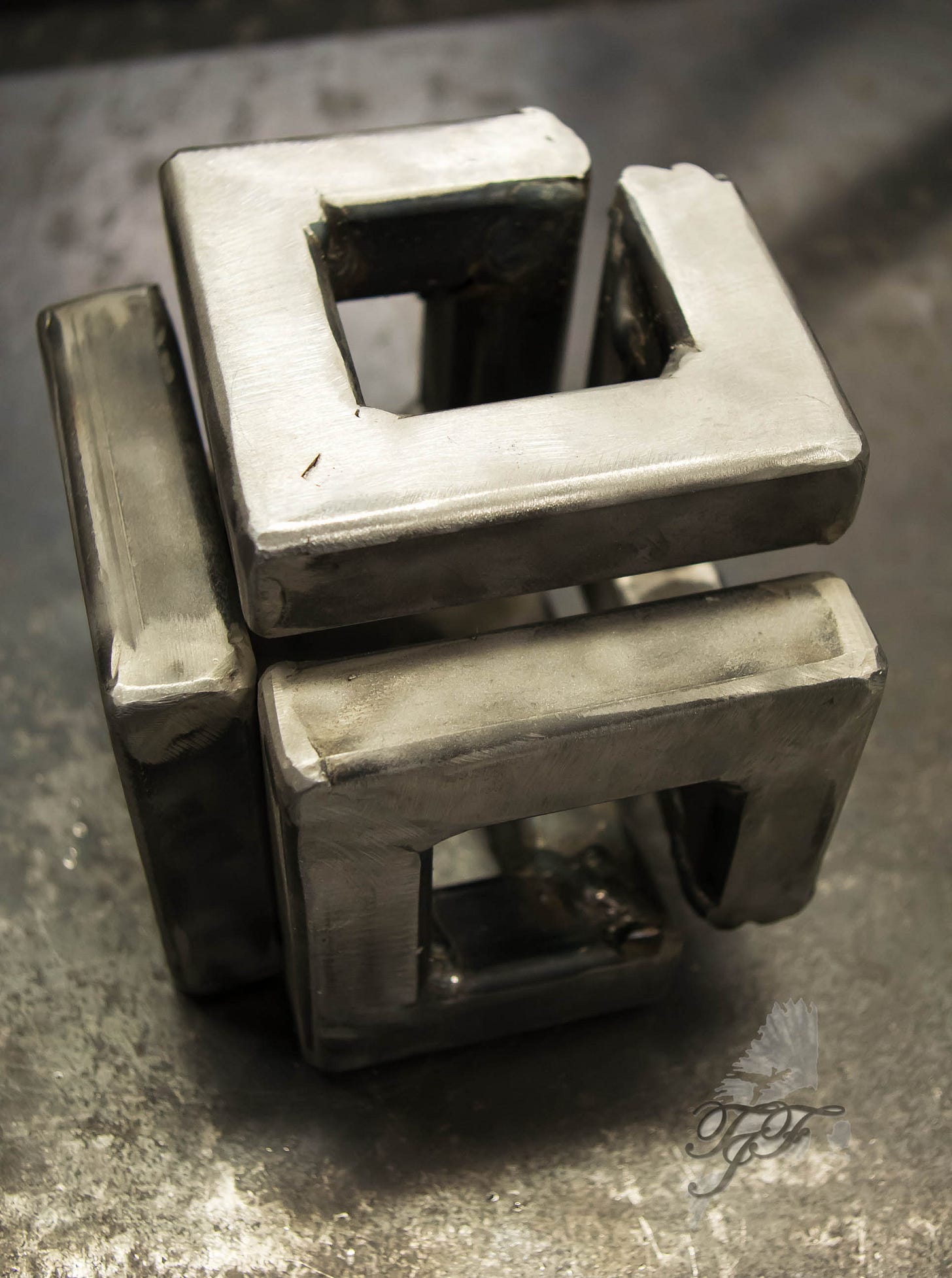

So, McColm started the students off learning to accurately measure, cut and weld by building infinity cubes, working in teams from a visual set of plans, correctly identify all the angles, learn how to use the tools to assemble them properly, and then they weld the cube in three sections before welding the whole thing together.

“When they’ve completed that, they come out of it as a team, they understand how to divide up tasks, they’ve learned how to support each other, and they’ve filled in any existing skill gaps that they had.”

The emphasis is on repeatability of the techniques.

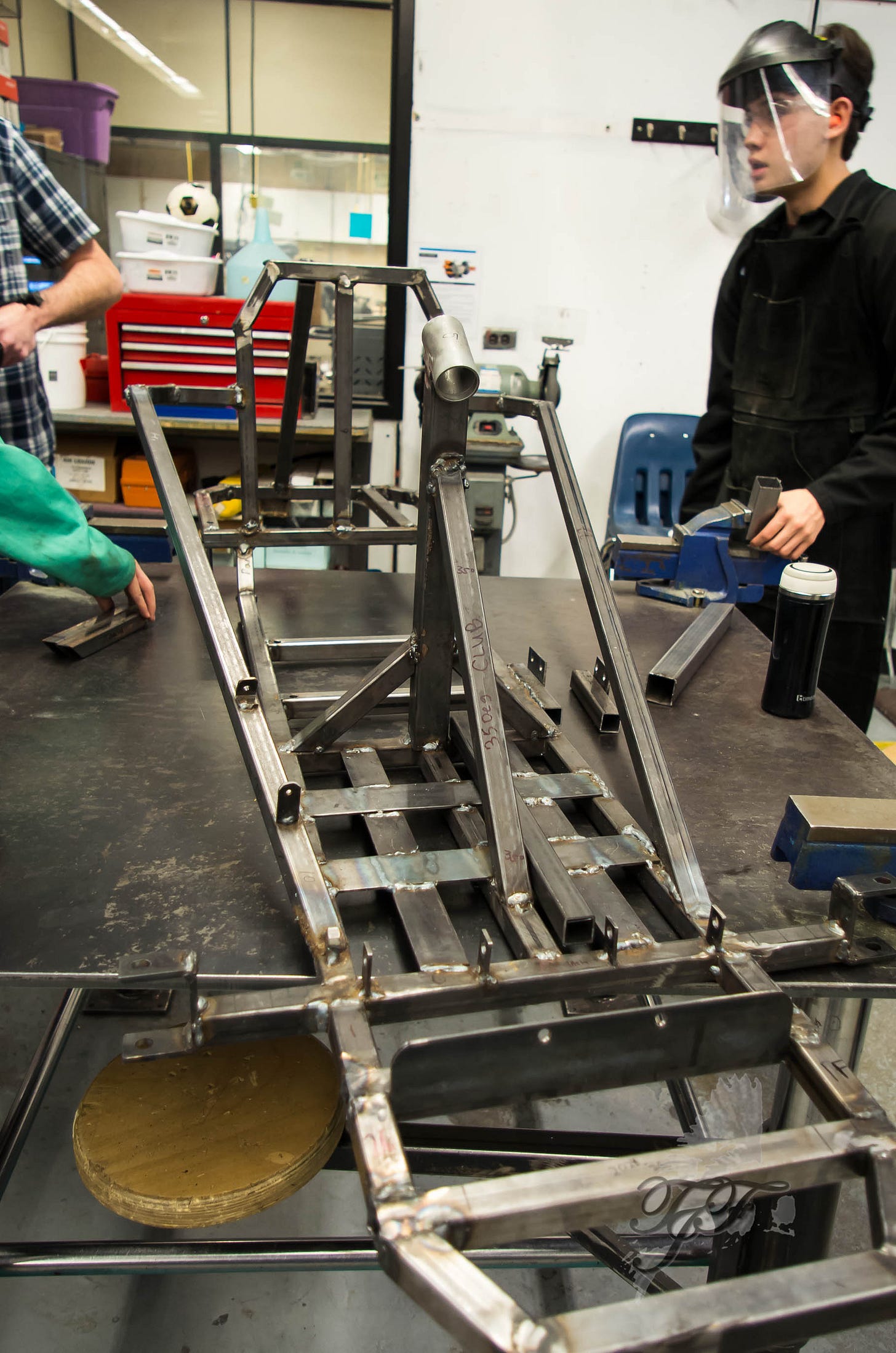

“This isn’t just a typical kid attempt at building a go kart, they’re led through the process of precision measurement, precision cutting, precision fitting and precision welding. They’re led through the processes of troubleshooting.”

In welding for example, the steel warps and bends and twists, so they learn to correctly weld in a way that doesn’t cause the steel to warp the planned shape.

Part of that repeatability is working off a “pattern” created through trial and error by McColm and the students in last year’s club. That pattern is the template for this year’s go karts.

Once they’ve cut pieces, they often bring them back to the “pattern” go kart frame to double-check that their angles match, proving the repeatability of what they’re doing.

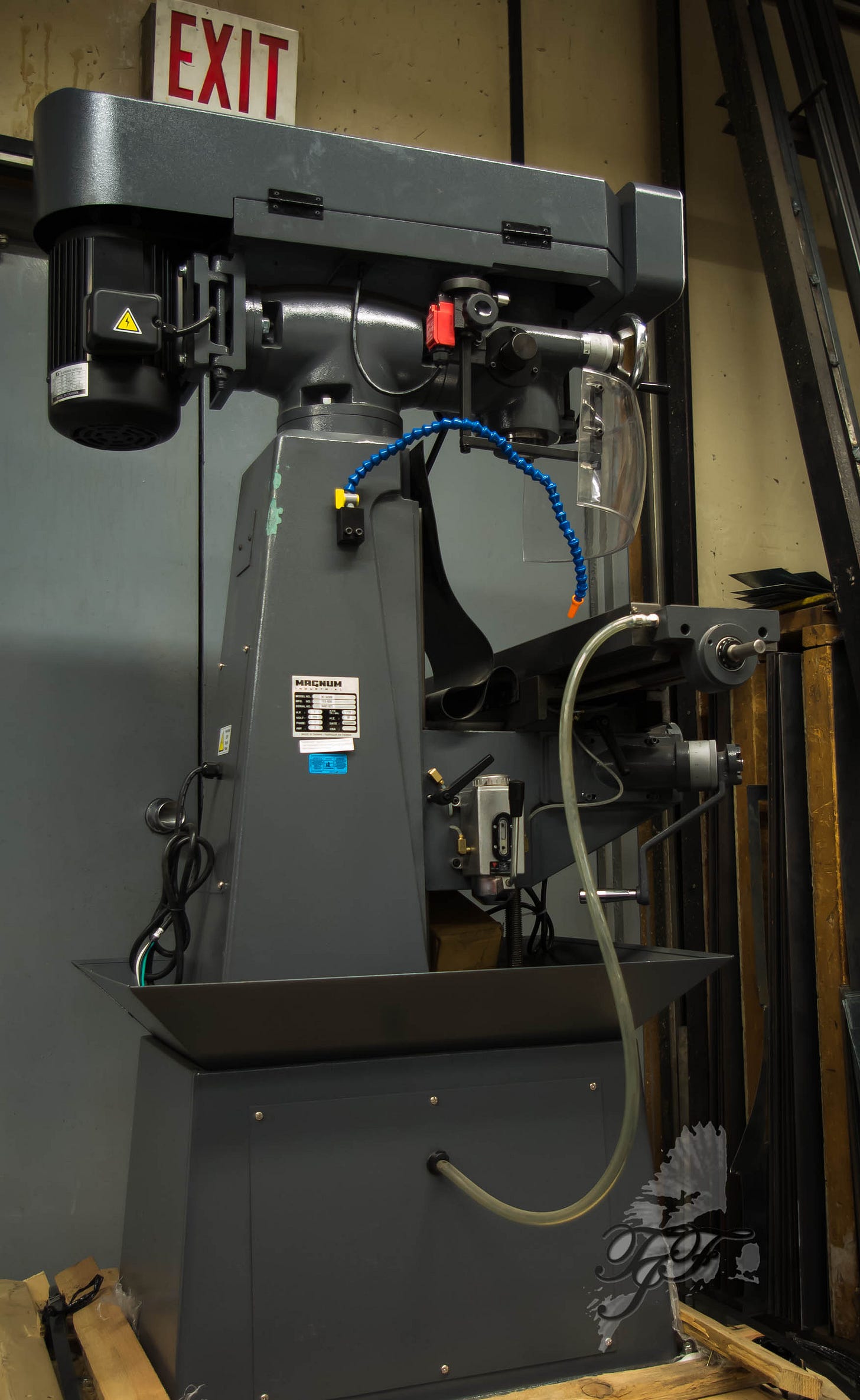

Unfortunately, to make the go karts, McColm says he has had to buy some premade parts, like brakes and axles, because although the Dr. Kearney metal shop received a milling machine on January 7, it’s lacking the tooling necessary to be able to use it.

“That’s used for operations that involve cutting channels in steel, if you’re creating an axle, if you’re cutting a gouge on one side of a shaft in order to put a locking pin in, that’s the machine that you would use. For cutting oblong slots in a piece of metal, you would use that. It’s a very versatile machine; you can also use it for creating custom gears and that kind of thing. It opens up the options for teaching students about machining operations,” McColm explained.

The school also doesn’t have a lathe, which would be used to create cylindrical parts, but like the milling machine, is a very versatile tool for cutting, shaping, drilling, and sanding.

So, they’re forced to create interface parts, taking parts, they can buy and customizing it for what they’re building, such as finding a way to attach the brake caliper to the frame that they built. For now, McColm is teaching the students to use CAD (computer aided drawing) to create patterns to build the interface parts.

Dr. Kearney’s PAC has graciously promised to buy the school a lathe, McColm said. “We really need it to compliment the milling machine.”

It’s not just about building a go kart that matches the template. It’s about creating something that the kids can use and enjoy.

“One of the ways to make the program meaningful for the kids is to promise them that they’ll actually get to ride the go karts they make.”

Before moving to Dr. Kearney, McColm taught at Prespatou Elementary-Secondary School where he guided students through the design, fabrication and building of electric go-karts with EV kits supplied by Edison Motors. Students then travelled to Merritt where they took part in an Edison Motors-sponsored go kart competition, with Prespatou’s go kart winning an innovative design award.

That experience, and the students’ enjoyment of it, inspired McColm to repeat the challenge for the Dr. Kearney students. But with Edison Motors no longer allowing anyone to take part in the competition who doesn’t have a driver’s license, he decided to come up with his own competition.

McColm has blocked out the last Friday in May – May 29th – and plans to take the students in all the metal shop classes who have contributed to building the go karts as well as those in the after-school club, to the first-ever SD60 Go Kart Rodeo. He would also like to bring together as many of the SD60 schools that want to participate. Schools in Fort Nelson and Dawson Creek, Hudson’s Hope also welcome to participate.

To complete the go karts, and continue with the program, McColm is seeking donations to help buy tooling, and steel for the go karts, and for the students to practice their skills on.

Each go kart requires wheels, steering wheels, seats, torque converters.

“There’s so many different pieces to make this program run,” he said.

Now that the school has a milling machine, McColm says they need milling cutters as well as sharpeners for the cutters because they will need frequent sharpening as they’re being used by students.

Tooling for the lathe will be needed. They are currently using Miller welders and have three of those, but the older one will need replacing soon.

“We’re chewing through a lot of steel to make the go karts and parts – ABC Recycling has helped out with cut-offs and small ends to practice on.”

Any donations to school that would allow McColm to buy steel would be very welcome. For example, the 4’ x 4’ sheet of 3/16 plate steel that is used to learn about CAD and manufacture brackets etc., to attach the purchased parts costs about $300.

If any businesses or individuals are interested in donating to help the After-School Go Kart program finish its three go karts, you can contact the school at 250-785-8378, or William McColm by email at wmccolm@prn.bc.ca